How to Lay Engineered Wood Flooring

Jump straight to:

> Tools You'll Need

> Your Installation Options

> Preparing to Fit Your Floor

> Installing Your Floor

> Finishing the Look

> Your Flooring is Finished!

or Download the guide as a PDF

To install these floors yourself you’ll need some tools to help with the job.

Have these at hand:

- Tape measure

- Spirit level

- Pencil

- Workbench or sawhorse

- Combination square

- Planks of flooring

- Spacers, Tapping block & Pull bar

- Rubber mallet

- Underlay and underlay tape (if needed)

- Handsaw or electric saw

- Chisel (for fitting around architrave)

- Drill (for covering pipework)

- Moisture meter – the correct type for your subfloor

- Beading or skirting boards (to finish the look)

- Adhesive and trowel (for gluing installation)

- Flooring nailer or Tongue-Tite screws and screwdriver bit (for nailing installation)

- Safety precautions i.e. knee pads, safety goggles, dust masks, ear defenders

Your Installation Options

Our Engineered Flooring can be installed in three different ways, so it depends on your joining method, the subfloor and what sort of method you prefer.

Note: This guide is based on straight plank engineered wood flooring, so if you're fitting parquet, please take a look at your parquet-specific guide.

Floating floor

In a floating floor, the boards are joined to each other, instead of to the subfloor. If you have a click-joining floor, floating is the way to go. If not, you could still use this method by gluing the tongue and the groove joints together. Either way, we’d advise you to have underlay installed and prepped.

Nailing

With this method, secret nails go through the tongue to secure the planks to a wooden subfloor. Because of this, nailing is only suitable for tongue & groove floors, not click-fit. Professional fitters tend to prefer this method as the result is extremely secure. You’ll need to fit a wood layer above any concrete because secret nailing cannot be done directly on top of a concrete subfloor.

Good to know

Tongue & Groove

These boards come with a short protruding side (the tongue) and one short indented side (the groove). These slot together like a jigsaw puzzle to form a tight fit.

Click-fit

These boards simply lock into place so are easier to install. We would normally recommend floating floors for this joining method.

Gluing

With this method, adhesive is applied to the top of the subfloor with a trowel and then the individual planks are laid on top. This is our favoured method for tongue & groove flooring but isn’t recommended for most click-fit boards. The exception to the rule is if you’re installing your click-fit floor over underfloor heating. In this case, adhesive can help keep the floor stable with fluctuating temperatures and can reduce creaky floorboards.

Preparing to Fit Your Floor

- Check the packs

Once the flooring arrives you should check one box to make sure you’re happy with the product. Due to the nature of wooden flooring, each plank is unique so there might be some natural variation between the planks and batches. When you get to laying the floor you can make the most of these colour contrasts by mixing and matching planks from different packs to get a lovely natural look.

- Leave to acclimatise

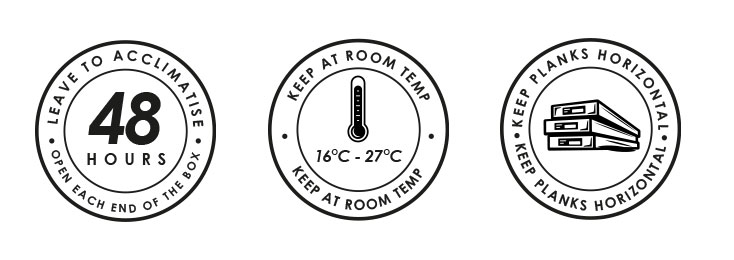

Your engineered wood floor should be left for 48 hours in the room it’s going to be fitted in. This time allows the floor to acclimatise and will reduce the risk of swelling or contracting once the floor is installed. To do this, either lay the packs on the floor or in stacks, just as long as they stay horizontal and that there’s equal weight distributed across them all. Leave the planks in their packaging but open each end to let some air in. Try to make sure the room stays at the same temperature you’d usually have it at so between 16°C - 27°C and don’t allow the floors to be exposed to the elements. If you’re using underfloor heating, you’ll need to gradually increase the temperature to get the wood used to the heat. Refer to the advice given by your heating supplier on how to do this.

- Prepare the subfloor

Before you lay your new floor, you’ll need to remove the existing flooring, prepare the subfloor and ensure it is clean, dry and level. We recommend a concrete or wooden subfloor for the best results. Use a moisture meter to check the subfloor is dry enough before you start. If you do have a concrete subfloor, make sure it’s completely dry before installation. A damp-proof membrane should be installed on top of the subfloor to reduce the risk of moisture reaching the engineered boards. You’ll need to do this to prevent the wood floors from expanding and buckling (many underlays now come with built-in damp-proof membranes). Any screws or nails in your subfloor should be fixed below the surface. This is so you can be sure they won’t puncture through the underlay (if you’re using it). Remove any old adhesive from previous floors and vacuum the floor to pick up any excess dust or debris. Now’s the time to get your underlay down if you’re using it. Roll it out in the same direction as you’re fitting the floor and secure the rows together with tape. - Plan the look

Before you start laying your floor, take the planks from the pack and look at the natural grains and variations in the shade. Pick out your favourites and use these planks as a focal point. Mix and match shades and patterns around these so that you can get a look you’re happy with. If there are a few planks you don’t love as much you could set these aside to use for cuts, or in areas that will be covered by furniture or rugs. Think about the direction you’d like your planks to lie. As a general rule of thumb, lay the boards against the longest wall for the best effect. If it’s a square room you might want to follow the room’s light flow, or follow on from the entrance. The majority of our fixed length planks come with a starter plank in the pack. This is a shorter piece of wood that you should use to begin laying the pattern so that the flooring has a staggered effect. For random length planks, mix and match the lengths so you get a dappled natural look. - And one last thing...

It’s best to fit your floor as the last thing you do in a renovation project. Work your way from the top of the room to the bottom so that once you’re ready for the floor to go in, there’s much less chance of damaging it. If you have a kitchen island, this can be installed on top of the floor as long as the subfloor is level. Don’t screw the island feet directly into the floor, as this would affect the wood’s natural contractions accounted for by the expansion gaps. If you’re installing furniture that is extremely heavy then you might wish to glue the floor down with adhesive for extra stability.

Installing Your Floor

- Before laying the boards, measure the width of the final row. You can do this by dividing the total width of the room by the width of an individual board. This will allow you to cut down the first row of boards to ensure the final row is at least 60mm wide.

- You can then lay the first plank in the corner of the longest wall with the tongue side of the plank facing the wall. Make sure this row is perfectly straight as this will set the direction for the rest of the floor.

- Place spacers between the first row and the walls to make an expansion gap of 10-12mm. Expansion gaps are important for seasonal changes where the wood may expand or contract (this is usually more of an issue with solid wood products).

- If your planks have a click-joining method, you will be able to continue to click the boards into place. If they have a tongue & groove joining method, then glue the groove before joining it to the tongue. You can then use a rubber mallet and tapping block to ensure the tongue & groove is secure.

- Continue to stagger the joints from row to row to create a natural wood appearance.

- Make sure you place spacers consistently to ensure a standard gap from the sidewalls.

- The last row might be tricky, but a pull bar and rubber mallet can help to create a tight fit.

- Before laying the boards, measure the width of the final row. You can do this by dividing the total width of the room by the width of an individual board. This will allow you to cut down the first row of boards to ensure the final row is at least 60mm wide.

- Apply the adhesive 1 metre out from the longest wall before laying your first row.

- You should lay the first plank in the corner of the longest wall with the tongue side of the plank facing the wall. Make sure this row is perfectly straight as this will set the direction for the rest of the floor.

- Place spacers between the first row and the wall to create an expansion gap of 10-12mm.

- As you continue, ensure you place approximately 1 metre of adhesive ahead of the previous row and stagger the joints from row to row to create a natural wood appearance.

- Make sure you place spacers consistently to ensure a standard gap from the sidewalls.

- The last row might be tricky, but a pull bar and rubber mallet can help to create a tight fit.

- Leave the floor for 24 hours before moving furniture back into the room or walking on it.

- Before laying the boards, measure the width of the final row. You can do this by dividing the total width of the room by the width of an individual board. This will allow you to cut down the first row of boards to ensure the final row is at least 60mm wide.

- You can then lay the first plank in the corner of the longest wall with the groove side of the plank facing the wall. Make sure this row is perfectly straight as this will set the direction for the rest of the floor.

- Place spacers between the first row and the wall to create an expansion gap of 10-12mm.

- We recommend surface nailing the first row of boards with a nail gun to guarantee they are well secured to the wooden subfloor.

- Then you can lay and secret nail the new row with a powered flooring nailer or by hand with Tongue-Tite screws and a screwdriver bit. These nails will go through the tongue and into the subfloor and will be hidden when the tongue fits into the groove.

- Continue to stagger the joints from row to row to create a natural wood appearance.

- Make sure you place spacers consistently to ensure a standard gap from the sidewalls.

- The last row might be tricky but a pull bar and rubber mallet will help to create a tight fit. You probably won’t have much room here so, as with the first row, you should surface nail.

Finishing the Look

To fit an engineered floor around any pipes, first mark the position of the pipe in the board you’re using. Drill a hole in this position and make two angled cuts with a saw. These cuts should form a wedge from the edge of the board to the hole which can then be removed. Fit the board around the hole and then reattach this wedge with glue behind the pipe so the plank looks intact.

For fitting around door frames, start by removing the door from the frame. Line up an offcut of flooring along with a threshold bar stacked on top to make sure it will fit underneath the architrave. If needed, use a handsaw and chisel to trim the bottom of the architrave to the correct height. You may also need to trim the bottom of the door before refitting.

You can then use matching beading and thresholds to cover expansion gaps and blend the new floors in with your existing walls, making it look professional and seamless. Make sure not to attach any trims to the flooring itself or it may affect the expansion gaps.

Any spare planks or cuttings can be kept in case any repairs need to be made.

If the expansion gap has been left too large and the skirting or moulding doesn’t cover it, you can use

spare floorboards to cut strips using a hand saw and glue these strips into place.

Forgotten something? It's not too late to order these...

Your Flooring is Finished!

After putting in the finishing touches (like our range of beautiful radiator pipe covers, skirting boards, stair nosing, and door profiles), you can introduce your furniture, stand back and take it all in. You just fitted your very own Luxury Floor!

We’d love to see your accomplishments! So make sure you take plenty of pictures and post them online

@luxuryflooringfurnishings on Instagram. Tag us #MyLuxuryFloor

We hope you’re happy with your new Engineered Wood Flooring but if you have any questions or issues, don’t hesitate to check out our advice centre or get in touch with our customer support team on 0333 577 0025.